Automatic machine monitoring

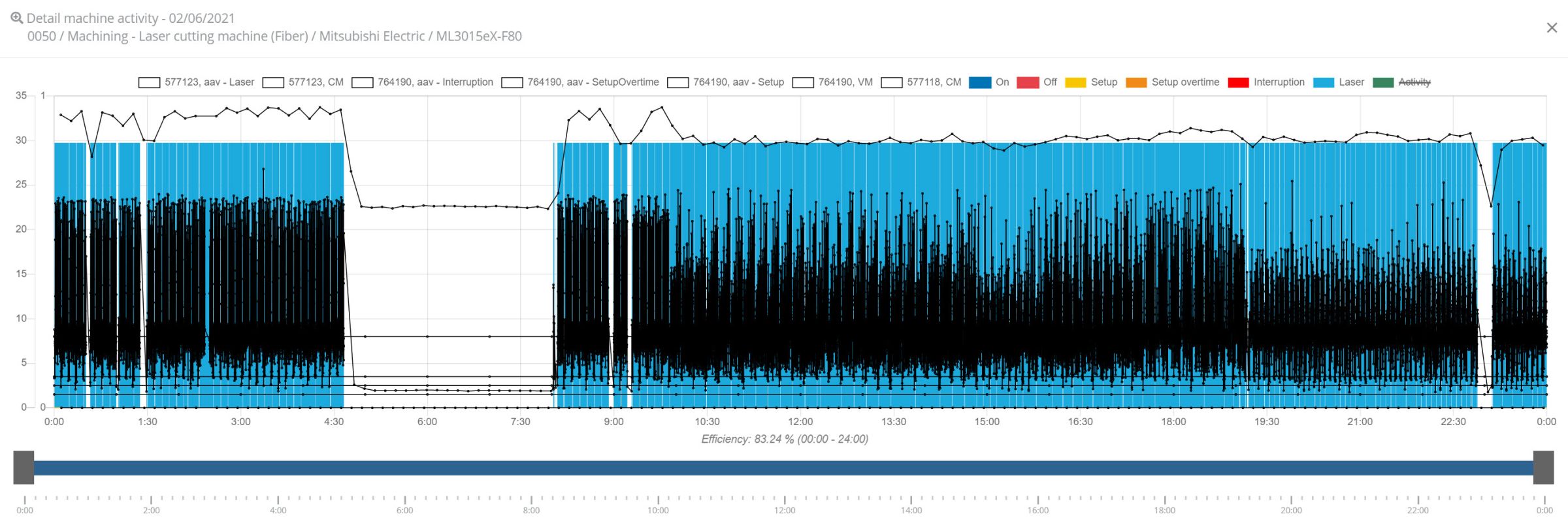

At the core of ZOOMFAB is a fully automated IIoT based machine monitoring system for collecting activity data of the machines and attached devices like robots, tool changers, storage and sorting systems, ovens, conveyors, etc. A standard system monitors when machines are switched ON or OFF, if they are idling or operating, how much energy they consume, and more. Optionally, ZOOMFAB can measure cutting gas consumption and instant flow rate.

Production data collection

To complement the data which is automatically collected from the machines, operators can be equipped with the 3rd generation Extended Data Collection terminal (EDC3), allowing them to record the data machines can't provide. In its basic form, the EDC3 terminal is used to record setups and production process interruptions, including both causes. The more advanced version of the EDC3+ terminal is also used to collect job-related data, which can be exchanged with ERP or other production management systems.

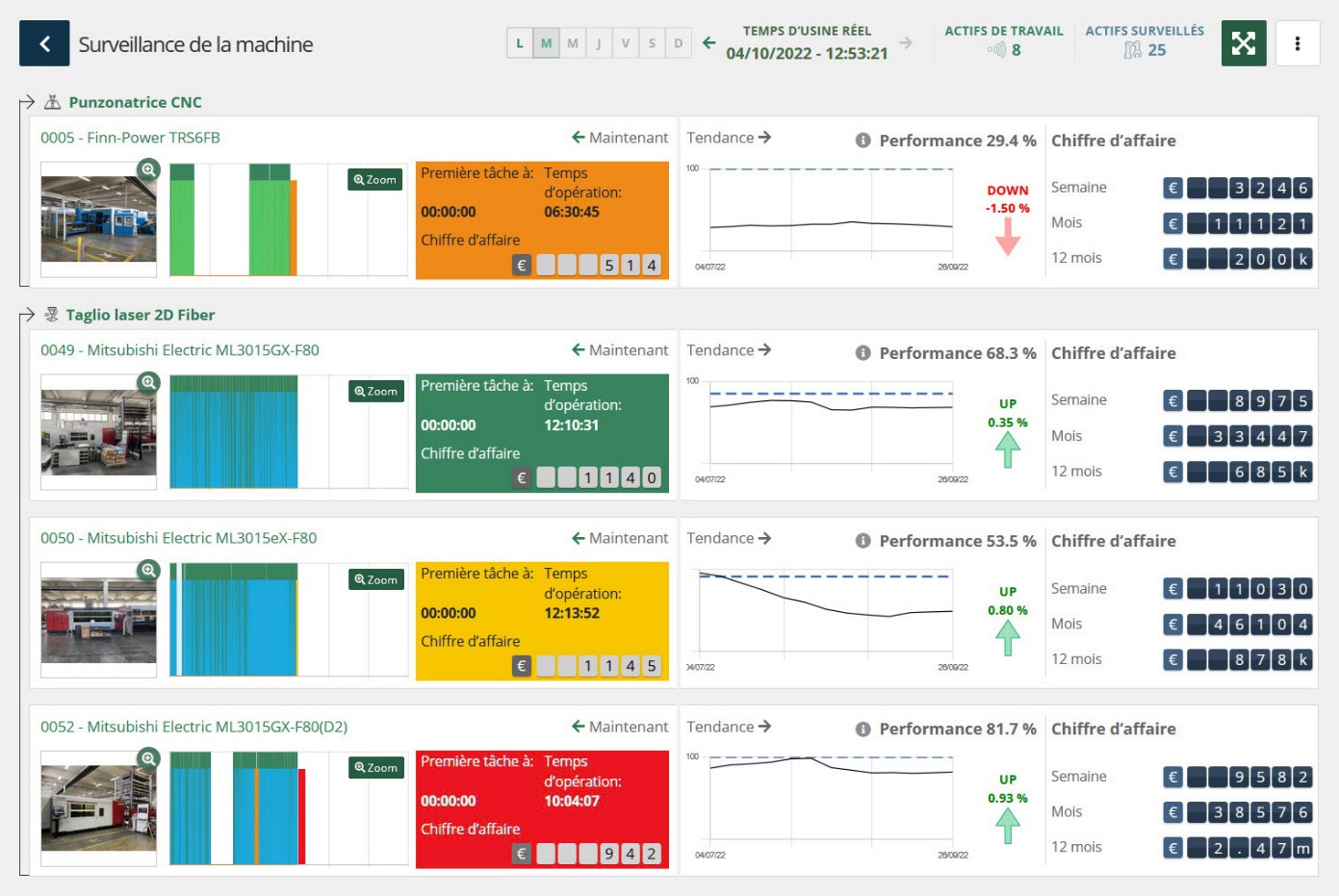

Real-time dashboards, alert & notifications

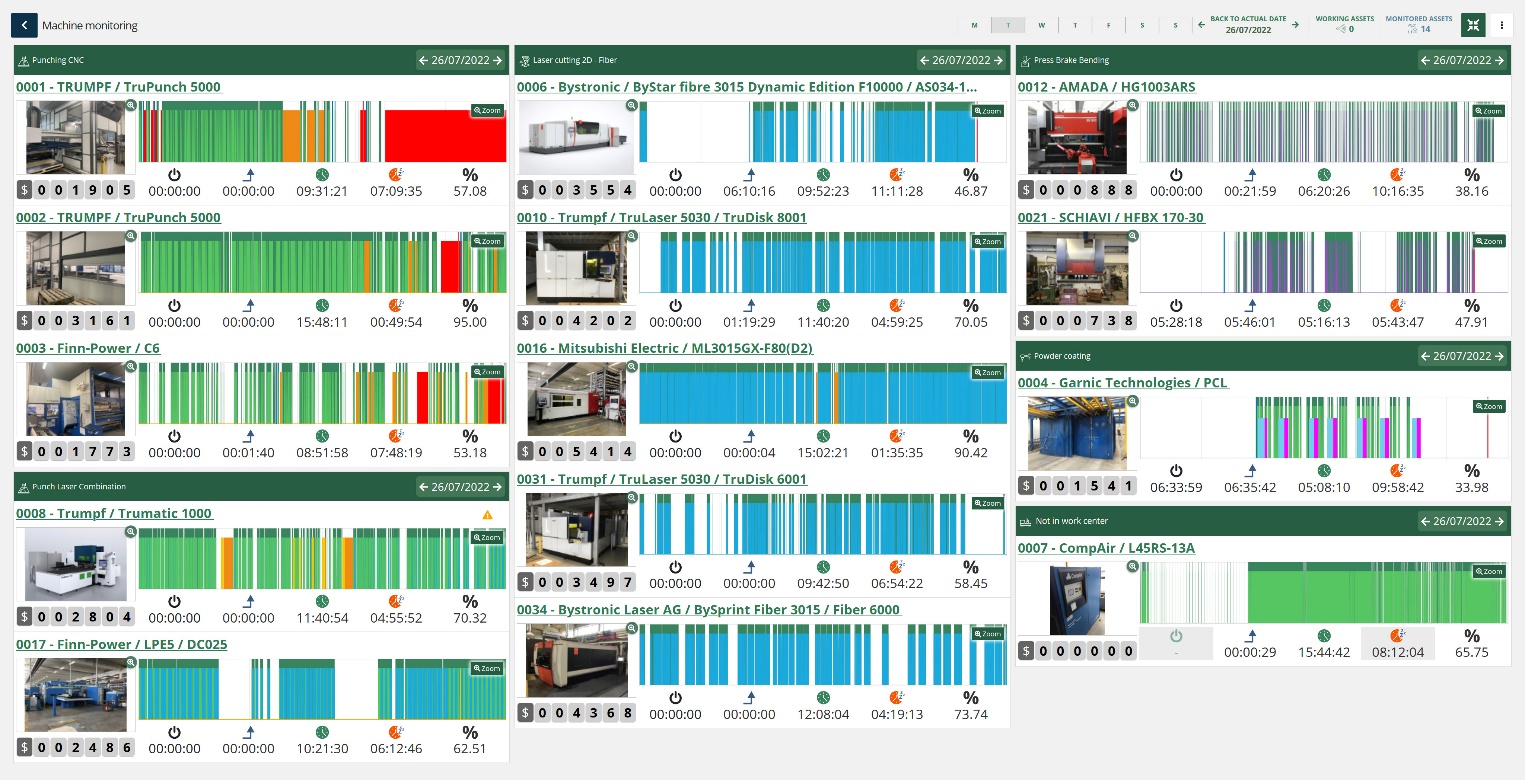

Data collected in real-time and data already in the system are constantly processed to provide users with an instant at-a-glance view of the key performance indicators and activity status. They also include planned and actual results comparisons, metrics for urgent decisions, alarms and notifications. The system has several preconfigured dashboards addressing shop floor activity, performance and trends. In addition, there are further dashboards addressing the impact of productivity on financial performance, asset management and energy management. In case of machine failure or stoppage, the system can forward notifications via email or SMS.

Real-time shop floor visibility

One of the most important benefits of ZOOMFAB is that it captures the situation on the shop floor in real-time and provides the user with powerful visualisation, including machine activity status, OEE, up-to-the-minute utilisation pattern, energy consumption, comprehensive statistics, trends and more. In addition, it highlights problems like excessive setup time or machine breakdown, which require special attention. In today's competitive environment, this can no longer be achieved efficiently by personal shop floor inspections or video surveillance. ZOOMFAB helps dramatically reduce downtime. It also saves the owner and managers valuable time, who can focus on other important tasks.